Especialidades farmacéuticas

Cartera diversificada de productos innovadores propios y comercializados bajo licencia, protegida por patentes.

Heparina de Bajo Peso Molecular

Nuestro principal producto, una heparina de bajo peso molecular desarrollada internamente.

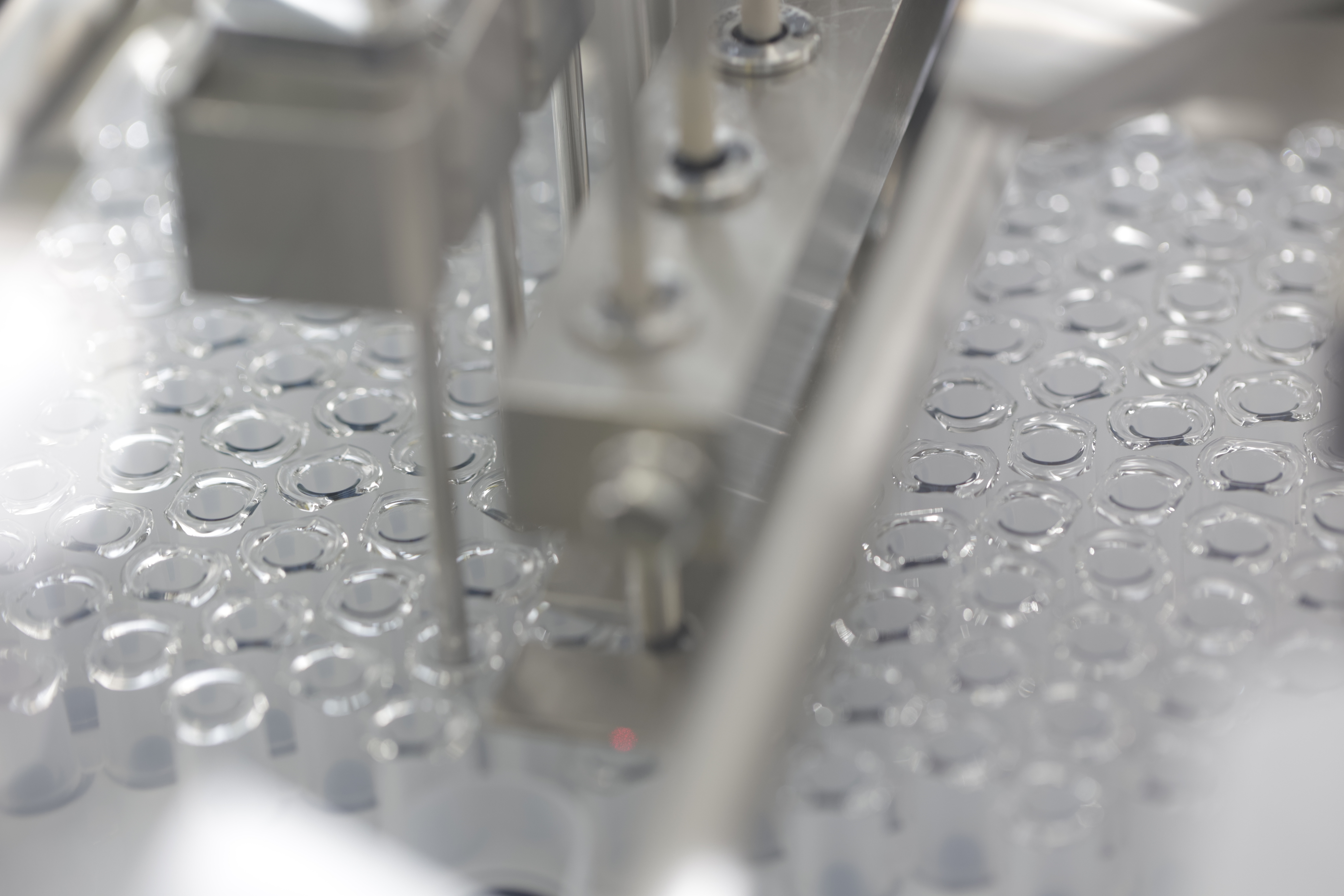

CDMO

Alta capacidad productiva con tres plantas de fabricación de jeringas precargadas y formas sólidas orales.

Rovi en cifras

829,5 Mn€

Ingresos operativosen 2023

420,2 Mn€

Negocio de Especialidades Farmacéuticas(+1% vs 2022)

Más de 90 países

Presencia de HBPM a través de alianzas estratégicas con socios internacionales

24,9 Mn€

Inversión en I+D en 2023 (+4% vs 2022)

409,3 Mn€

Ventas de CDMO(+1% vs 2022)

42,85%

Porcentaje de mujeres en el Concejo de Administración

Espacio del inversor

Información al detalle para inversores y accionistas. Todos nuestros datos, resultados y cifras de forma clara y transparente.

Actualidad Rovi

Último Informe Anual

Informe Anual 2023

Última información

pública periódica